Products

Brands

RAPID metal separator for free-fall applications

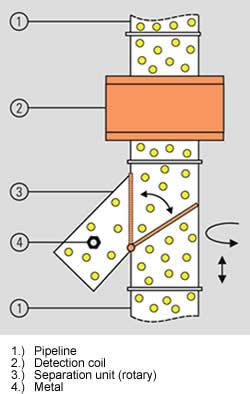

RAPID metal separators remove magnetic and non-magnetic metal particles (steel, stainless steel, aluminium etc) from free-falling bulk materials. Metal contaminants (even those contained in granulate) are removed by means of a specially designed reject flap (“Quick Flap System”). A further advantage of the “Quick Flap System” is the minimal loss of good material.

- Detects and removes even the smallest magnetic and non-magnetic metal particles from regranulates, virgin material and other bulk materials

- Reduces production down-times and damage to machinery

- Reduces costs and increases productivity

- Ensures metal-free bulk materials

- Product effect compensation: intrinsic

- Conductivity of bulk materials (e.g. from moisture or carbon) can be “tuned out” automatically

- Detection unit and reject mechanism are designed to be separated: drop height and direction of reject material can be easily adapted to suit specific requirements (reject mechanism can be rotated through 180°)

RAPID metal separators are used in the plastics industry primarily to protect machinery.

Expensive and time-consuming damage to machines and tooling is reduced, consequently productivity is considerably increased. The system can be easily integrated into existing vertical pipelines to protect grinding mills, cutting mills (cyclone) and dosing equipment (rotary feeders, vibrator chutes etc).

It is also a vital component in quality assurance and can be used equally well as part of an interim inspection procedure or as a final check prior to goods being dispatched. Mounted on a mobile stand the unit can be used for a wide variety of applications e.g. cleaning smaller loads. RAPID units are also suitable for similar applications in other industries (e.g. in the animal feedstuffs and chemical industries).

Typical applications:

- Plastics industry: machinery protection, quality assurance

- Food industry: quality assurance

- Chemical industry: quality assurance

- Recycling industry: machinery protection

- Wood industry: machinery protection

- Animal feedstuffs industry: quality assurance

RAPID metal separators offer the following performance features:

- Excellent metal detection, maximum resistance to interference and high mechanical and operational reliability

- Automatic self-calibration and ongoing self-monitoring and temperature adjustment

- Fully automatic process once optimal customisation of scanning sensitivity and reject duration is achieved

- Separation unit is normally supplied in stainless steel (1.4301)

- Detection unit and reject mechanism are designed to be separated enabling free-fall height and location of the reject outlet to be precisely positioned to suit on site conditions

- Extremely small overall height means it is easy to integrate into existing pipeline systems

- Standard pipe connections (Jacobs) speed up installation

- “Quick Flap System“ minimises loss of good material

- Options are available to accommodate materials at high temperature or abrasive bulk materials

Metro SF metal separator