Products

Brands

ENMA C300 Series Shredder

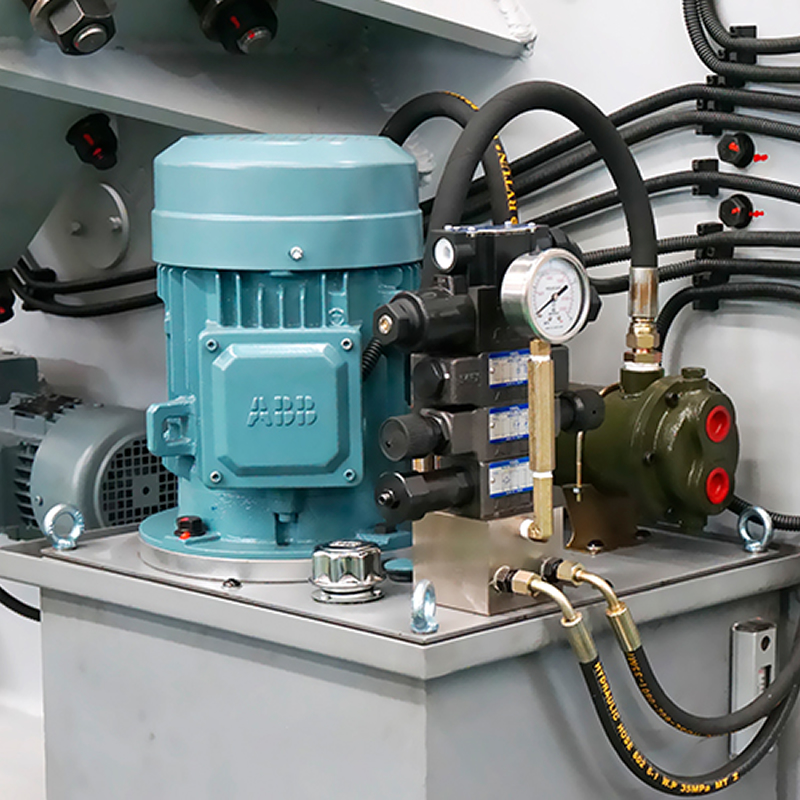

The C300 series shredder has a tangential in-feed which eliminates the need for a hydraulic feeding system. The compact foot print and easy installation means this machine is virtually plug and play.

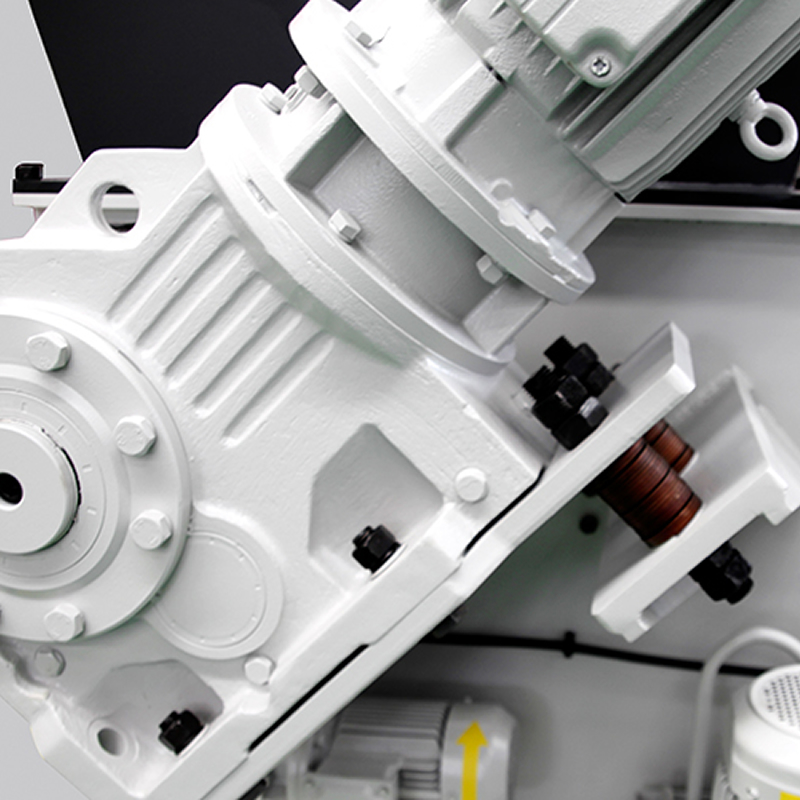

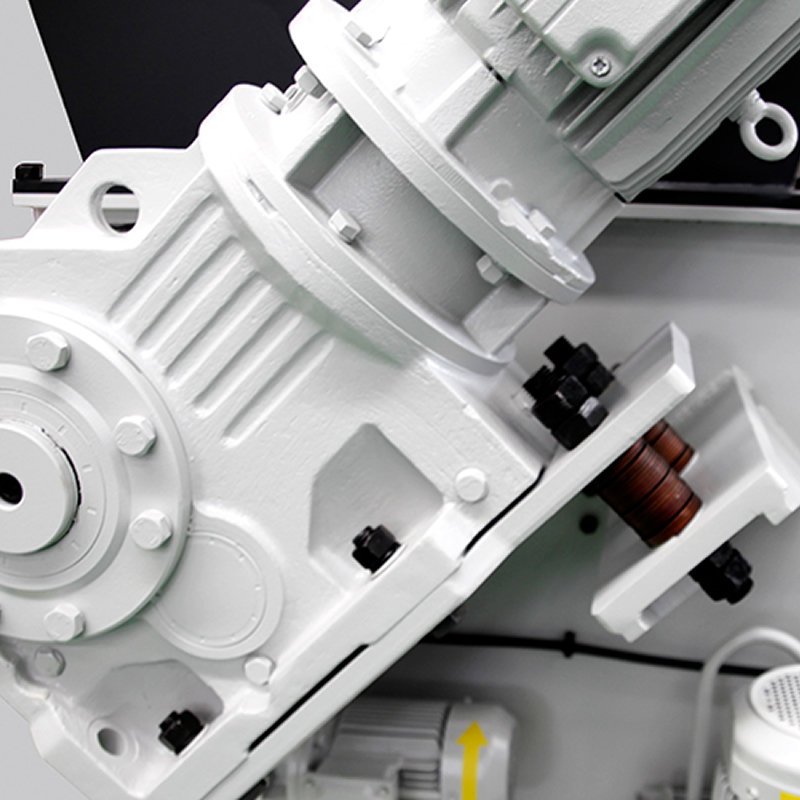

The C300 series is fitted with outboard bearings which support a 250mm rotor, this is available in two widths 600 or 800mm and is driven through a generously oversized gearbox.

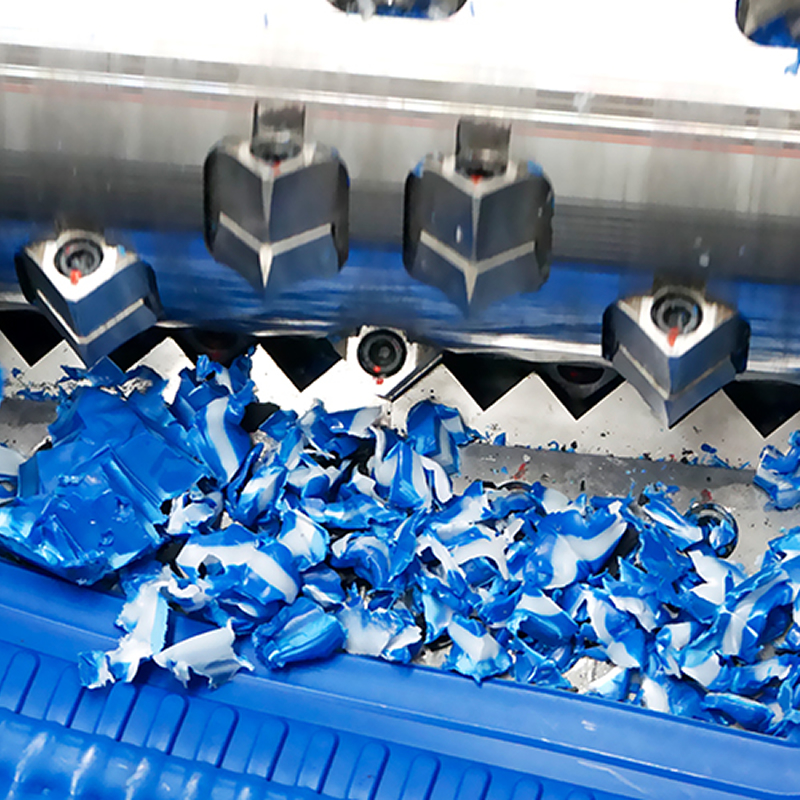

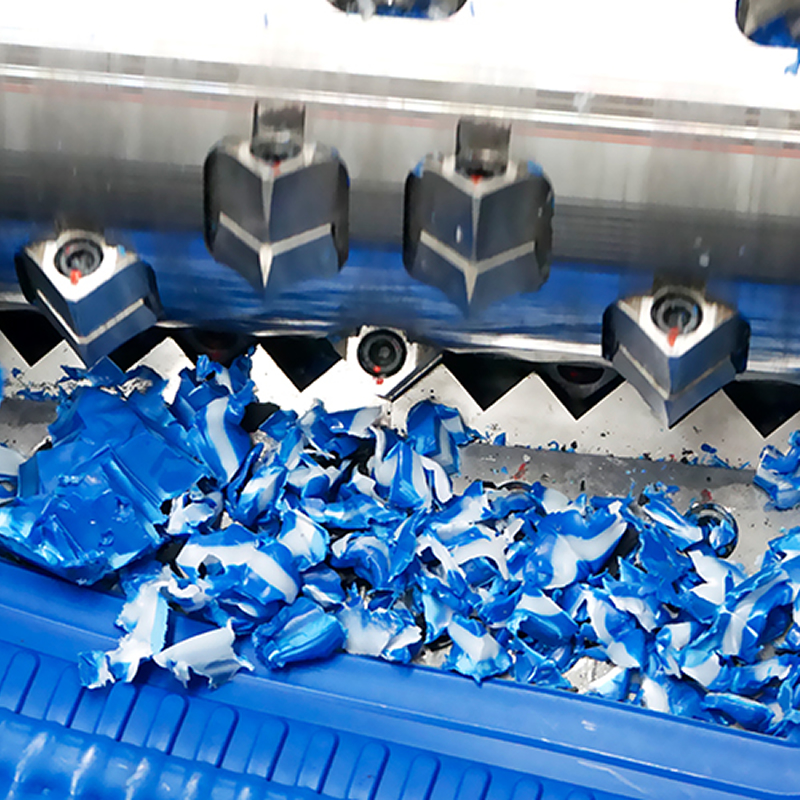

The same proven knife and holder design as used in the larger Enma shredders, the operator friendly design makes cleaning and maintenance easy. The low speed (60 rpm) rotor makes shredding lumps possible without excessive noise. The machines can be hand fed or using a conveyor. On the output side of the machine the shredded material can be transported away either using a belt conveyor or pneumatic conveying.

Benefits

- Safety is Enma's highest priority & this unit complies the the latest best practice.

- Affordable solution for lump material

- Works well as an inexpensive upgrade to an existing granulator system

- Easy to move and position

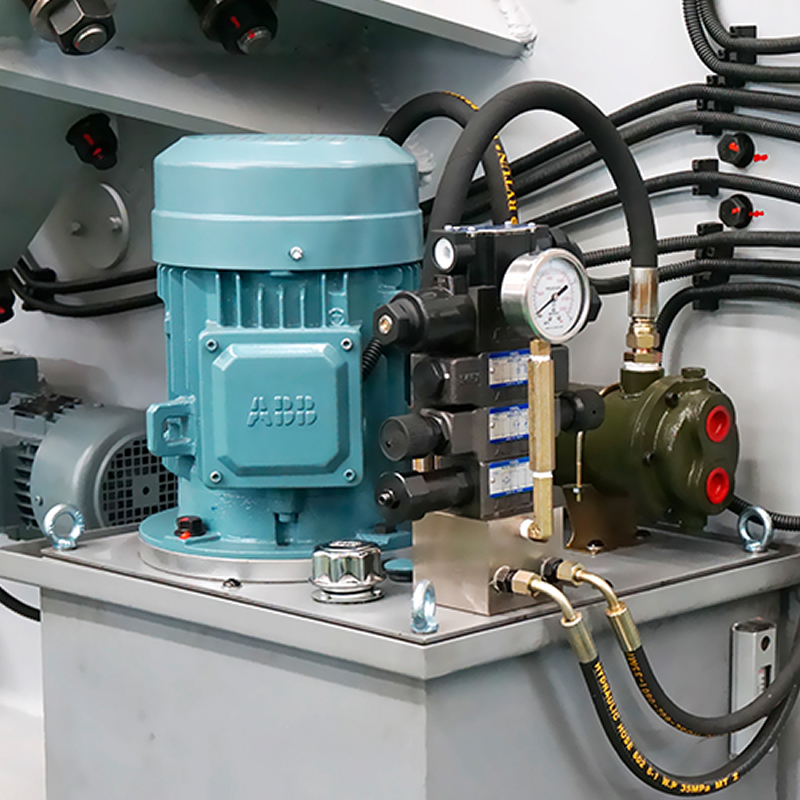

- Tangential in-feed avoids the need for hydraulics, reducing purchase & maintenance cost.

- Small footprint

- Low energy consumption.

Typical Applications

- Small lump / purgings from blow moulding applications

- Pre-shredding of large parts prior to granulation

- Recycling of small batches of material without contaminating the main line.

- Destruction of sensitive material for security.

Click here to submit your enquiry. We aim to respond within 1-2 hours.

![]() ENMA Shredder / Crusher Brochure

ENMA Shredder / Crusher Brochure

C300 Series Compact Lump Shredder

C300 Series Shredder in White

C300 Shredder Auger discharge

C300 Shredder Oversize Gearbox

C300 Shredder Pump

C300 Shredder Rotor Detail

C300 Shredder screen and extraction auger