Sectors

Animal Feed & PET FoodBiomass Pellets

Brewing & Distillation

Chemical, Paint, & Mortars

Food & Flour Milling

Plastics Recycling

Products

Brands

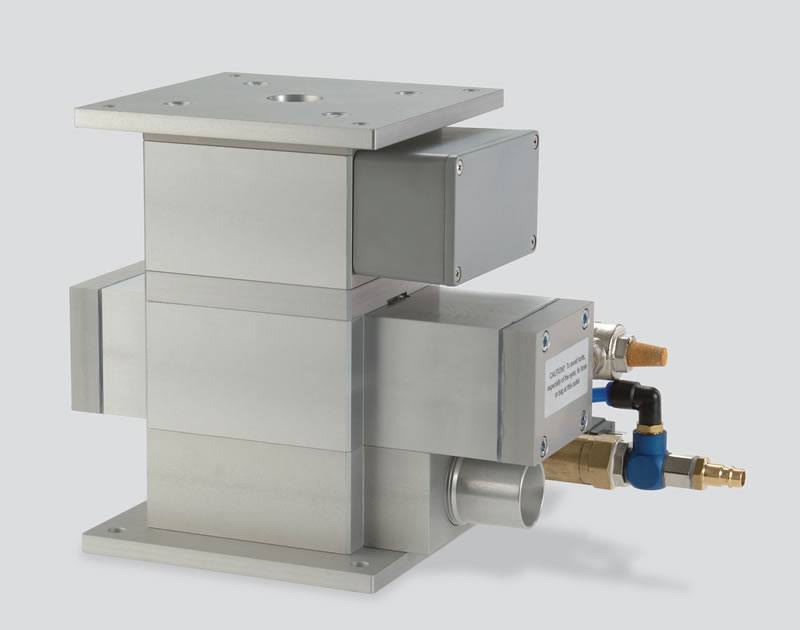

Protector metal separator for slow moving material column

The PROTECTOR metal separator is installed directly above the material in-feed of an extruder, injection moulding or blow moulding machine. Other features include high sensitivity across all metals, an extremely compact, space-saving design and the ability to operate successfully with all conveying systems especially vacuum conveyors.

- Detects and removes even the smallest magnetic and non-magnetic metal

- Particles from regranulates and virgin material

- Reduces breakdowns and machine down-times providing a rapid return on investment

- Ensures constant production process parameters

- “Last Chance” controller: directly above the material in-feed

- Product effect compensation: intrinsic conductivity of bulk materials (e.g. from moisture or carbon) can be “tuned out” automatically

- Patented reject mechanism ensures effective and reliable removal of contaminants

Even the smallest metal particles in molten plastic can cause expensive and time-consuming damage to extruders, injection and blow moulding machinery. As the use of plastic regranulates increases so does the probability of metal contamination, causing blockages in nozzles and filters.

However, machine breakdowns, loss of production and failure to deliver are not the only result; the cost of repairing an extruder spiral or cylinder damaged by just one single larger piece of metal is many times more expensive than the cost of a PROTECTOR system.

The PROTECTOR combines the proven benefits of existing metal separators for this application with improved performance features which we have developed in close co-operation with our customers. Machine availability and productivity are greatly increased providing a fast return on investment.

Typical applications:

- Automobile industry: bumpers

- Electronics industry: connector components

- Data processing: optical discs

- Household goods: housing components

- Drinks industry: bottle caps

- Construction industry: profiles

PROTECTOR metal separators offer the following performance features:

- Excellent metal detection, maximum resistance to interference and high mechanical and operational reliability

- Automatic self-calibration and continuous self-monitoring and temperature adjustment

- Fine tuning the metal separator to achieve optimal customisation of scanning sensitivity and reject duration ensures the entire process is fully automatic with no interruption to the flow of material

- Patented reject mechanism ensures effective and reliable removal of contaminants; there is very little risk of jamming, even with high proportions of regranulate (dust)

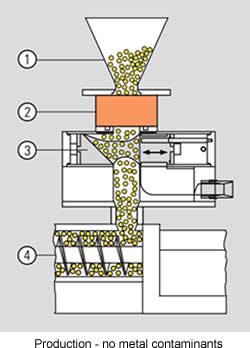

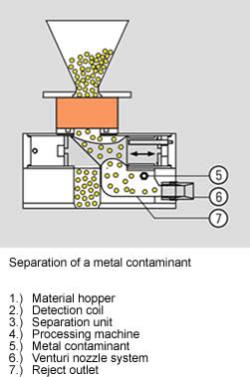

- Metal contaminants are removed into a reject material container by means of a separating slide and a Venturi nozzle system

- Due to its robust and compact design (aluminium block design), conveyor, mixing or dosing equipment can be attached to the detection and separation unit

- The pneumatically-driven reject system works so quickly that metal particles are consistently removed from free-falling granulate not only at the initial fill but also at subsequent top-ups

Metro SM metal separator